The Phrozen Sonic Mini 4K is an inexpensive desktop photopolymer 3D printer with amazing print quality and a 4K monochrome LCD screen. It’s very fast: it takes less than 2 seconds per layer. If you thought resin 3D printers were already great, the Prozen Sonic Mini 4K has raised that bar to 11.

Phrozen is one of the top three brands in the consumer resin 3D printer market, and the Sonic Mini 4K is an evolution of the original Sonic Mini.

Read the full review of 3D printer manufacturer Phrozen here – https://top3dshop.com/blog/phrozen-brand-review.

Design

- The design of the Sonic Mini 4K is virtually the same as the original Sonic Mini and actually resembles almost every other desktop printer in this price range.

- This is a compact printer that can be conveniently placed in the corner of your desk. It measures 10 inches (25 cm) square and is less than 12 inches (33 cm) tall, weighing only 5 kg.

- The translucent brown acrylic cover protects it from dust and sunlight, and you have to lift it up completely to get to the printing area. There are no hinged covers or other conveniences. The machine comes fully assembled, but the bed must be manually aligned before printing.

- An all-metal resin backplate and Z-axis make the Sonic Mini 4K more expensive than some cheaper printers, but that’s not uncommon in this category these days. Again, this is an improvement over the previous Sonic Mini with its multicolored plastic tray.

- The 2.8-inch touchscreen is also common and necessary, as is the lack of a network connection. All designs must be loaded using the USB port on the side.

Tool Kit

The box includes a complete tool kit: a plastic spatula, a metal scraper (not actually recommended for use as it tends to damage the assembly plate) and a chassis plate with an allen wrench that tightens the four bolts that hold the assembly together.

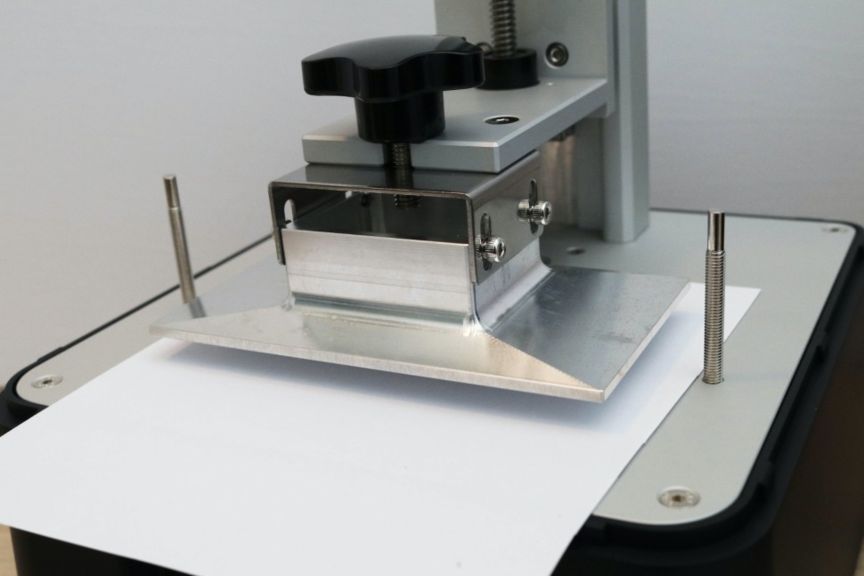

Aligning the platform

To level the platform, we remove the plastic batten (held in place by two knurled screws on each side), the assembly plate is loosened and loosely secured to the Z.

Then we put a sheet of paper on the screen and turn on the machine.

Use the tool to look for the “zero” button, allowing it to move down to the level of the screen, and press down on the build plate so that the paper does not move.

Tighten the bolt, and it’s done.

Once the build tray is in place, reattach the plastic bits.

These steps seem more complicated than they are, but they are important steps that probably only need to be done once. If you skip this step or make one side of the plate slightly higher than the other, the printing will fail, so take the time to get it right.

Distinguishing Features

A distinctive feature is that the build plate is larger than the average build plate. Compared to other printers in its class, a printer with a 135×75 mm work surface can pack much more material. However, the total build height of 130mm is actually a bit less than other printers.

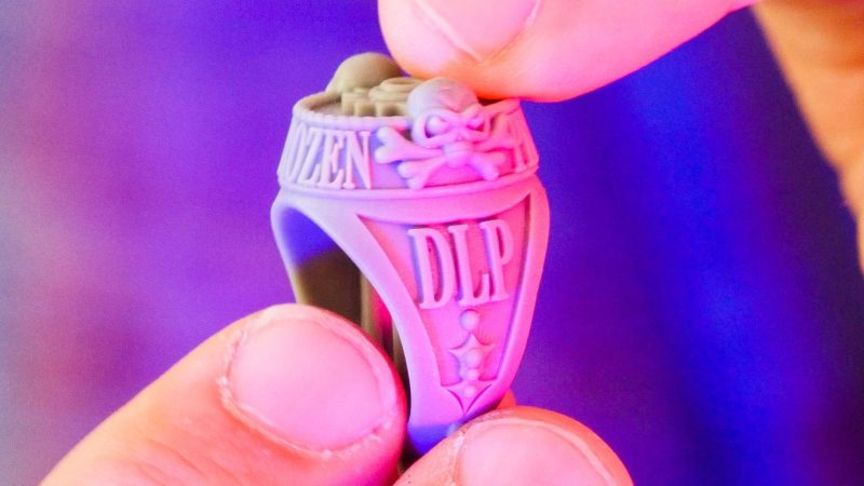

Still, you won’t need the height in most cases, but the extra tray space allows you to print more at a time. The Sonic Mini 4K is aimed directly at those who print a lot of small, highly detailed miniatures, jewelry or dental work. If you need a large print height, such as a tall vase, this option is not for you.

In terms of detail, the 4K resolution screen offers a staggering 722 PPI (pixels per inch), but the minimum layer height is 10 microns, which is the best detail you’ll ever get.

Of course, we expect other manufacturers to follow suit soon, but for now the Phrozen Sonic Mini 4K sets a new standard for budget printing and will ship in late September.

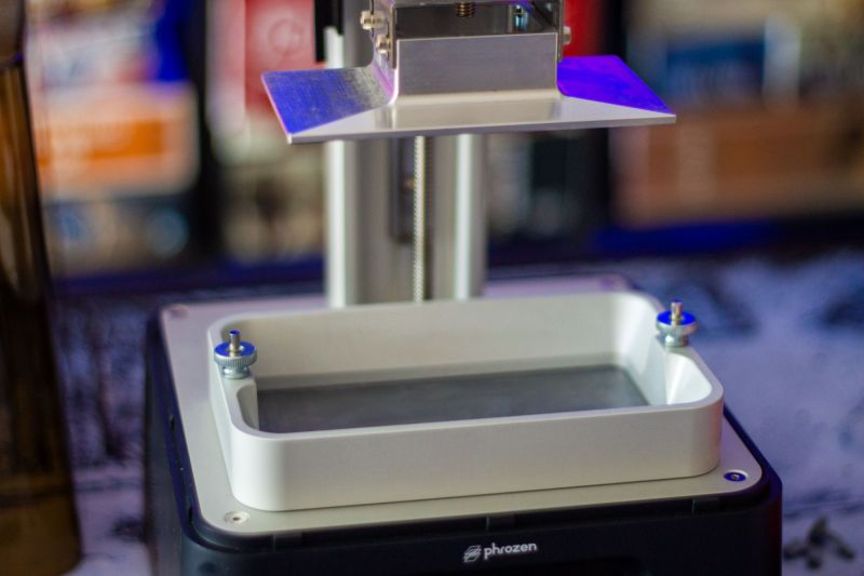

It takes less than 2 seconds per layer, so you can pump out a full tray of miniatures printed with a 0.05mm layer thickness in less than 3 hours, as shown in the photo below.

This speed is made possible by the use of a monochrome LCD, which transmits more intense light compared to a color LCD. The faster the UV light reaches the resin, the faster it cures. This, combined with the 405 nm ParaLED Matrix 2.0, provides a smooth and even distribution of light across the screen.

The Sonic Mini 4K is not so much a revolution as it is a refresh of the original Sonic Mini. That doesn’t diminish the importance of the 4K screen and the fast monochrome LCD. They certainly provide incredible print quality. In every other respect, however, the Sonic Mini 4K is not innovative.

It runs on the same industry-standard ChiTu firmware as almost every other resin printer on the market, so the workflow is familiar to anyone with 3D printing experience. If you’re new to ChiTuBox software, it comes down to loading the model, positioning it as needed, and adding supports (either manually or with automatic profiles). It then performs slicing (the process of splitting the print into thin layers) and saves it to disk.

The fact that you are using off-the-shelf software is not a bad thing (in fact, quite the opposite, given that you can find it in a huge support community). However, Phrozen’s innovation in hardware is limited. Only.

There is no built-in Wi-Fi, so you have to copy files to a USB drive, and you have to physically manipulate the touchscreen to start printing.

The design is all-metal and includes plastic batts, which increases reliability and durability of printing, although this is not the first printer to use this.

The Sonic Mini 4K is fast, reliable, and produces great prints. There are no particular problems with it, so it’s worth considering if you want more detail in your prints. It’s certainly an iterative upgrade, but an important one nonetheless.

However, if you are new to resin printing, you can get a satisfactory print without even cheaper printing. At the very least, it might be worth starting with something cheaper to see if resin printing is right for you.

The print quality you get from resin printers is usually excellent, and the Sonic Mini 4K is even better.

However, if you are new to 3D printing or resin printing in particular, there are a number of other factors to consider before investing in 3D printing.

As with all resin printers, the FEP batts resin film is a consumable and costs about $10-$15 per sheet to replace (and the labor to actually replace).

Screens also need to be replaced after about 2,000 hours of use. However, they last longer than the previous generation of color screens. A new screen for the Sonic Mini 4K costs about $90.

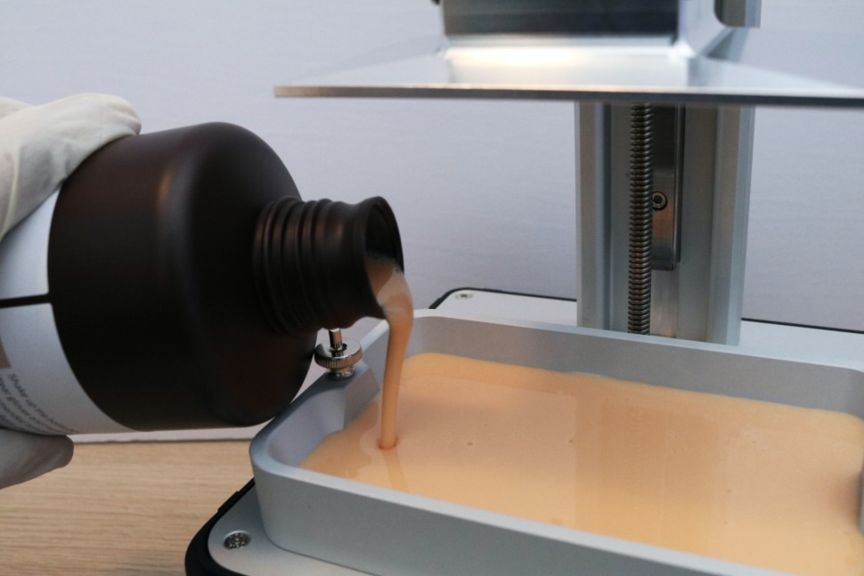

99% isopropyl alcohol is needed to wash the excess resin off the print. This costs about $30 for 5 liters, but everyone knows the basic ingredient in hand sanitizer, so prices vary considerably these days.

Next, you’ll need UV curing equipment. The right curing and cleaning station can cost several hundred dollars.

Printing on resin can be messy and dangerous and requires a lot of labor to process the printed material afterward. If you’re not ready for the hassle and effort involved, but still want to learn about 3D printing, a filament-based FDM printer might be better, but the results you get from it are not comparable.